Flexible Packaging

From mono-material and oxygen barrier coatings to UV-LED solutions, Sun Chemical has a wide range of flexible packaging solutions to improve pressroom efficiency, reduce waste and extend product shelf life.

Sustainable development at Sun Chemical is defined as the design of products or processes that reduce greenhouse gas emissions related to climate change, conserve virgin resources and/or lower the accumulation of waste compared to conventional products or processes they replace.

Sustainable development at Sun Chemical is defined as the design of products or processes that reduce greenhouse gas emissions related to climate change, conserve virgin resources and/or lower the accumulation of waste compared to conventional products or processes they replace.

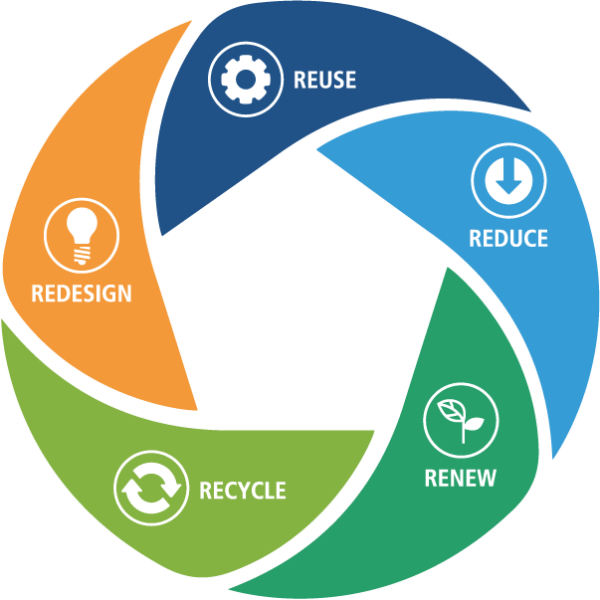

This definition aligns activities across a wide range of product technologies and market areas. Once we understand the needs or opportunities in any particular market segment, a “5R” framework organizes our activities and roadmap for sustainability-enabling technologies. These 5Rs are Reuse, Reduce, Renew, Recycle and Redesign—all of which support a circular economy and reductions in carbon footprint.

Sun Chemical’s pressroom products offer a fully integrated solution that includes pigment dispersions, inks, coatings and adhesives, as well as color management for the packaging market.

Our color materials solutions, including pigments, dyes and preparations, provide innovative conventional and effect solutions for the coatings, cosmetics, printing inks, plastics and specialties markets.

Our advanced materials are used within a wide range of applications and markets, including inkjet, electronics, circuit boards and printed electronics, automotive, aerospace, textiles and security, such as currency and passport applications.

Our advanced materials are used within a wide range of applications and markets, including inkjet, electronics, circuit boards and printed electronics, automotive, aerospace, textiles and security, such as currency and passport applications.

In each of these areas, sustainability is an important driver. Our 200+ years of experience, knowledge about the markets we serve and strong collaborations with downstream customers, whether packaging producers, designers and brand owners, masterbatch compounders, electronic material suppliers, cosmetic formulators, automotive suppliers or industrial applications, allow us to reimagine today’s materials and processes by designing innovative products and processes that meet the specifications and sustainability drivers across a diverse range of markets and applications.

This combination of expertise, understanding of industry trends and collaborations is what distinguishes Sun Chemical from its competition. We’re keen on providing you with the sustainable solutions you need to create unforgettable brand experiences that have a positive impact in the world.

We call it: Experience. Transformation.

Learn how we’re bringing our know-how to innovate world-class sustainable products under our SunEco umbrella of products.

From mono-material and oxygen barrier coatings to UV-LED solutions, Sun Chemical has a wide range of flexible packaging solutions to improve pressroom efficiency, reduce waste and extend product shelf life.

A wide selection of inks, coatings and adhesives for the NWTL market can reduce carbon footprint, increase pressroom efficiency, and improve the recyclability, biorenewability and compostability of labels.

Sun Chemical’s biorenewable inks, coatings and adhesives for paper packaging can play a big role in achieving compostability and recyclability goals of brand owners.

Sun Chemical offers unique ink offerings for folding cartons that allows you to print ‘inside the box’ and replace PE barriers while still ensuring the required resistance properties of the carton are maintained.

Sun Chemical offers a combination of color management and biorenewable inks and coatings to improve recycling and reduce pressroom waste when decorating two-piece, three-piece and monobloc aerosol metal cans.

Sun Chemical offers a wide selection of water-based sublimation, pigmented, acid-dye and reactive dye inks for digital textile printing that meet your requirements for high quality, vibrant and long lasting prints.

Learn how our color materials are developed to support our sustainable future for a wide variety of markets, including: automotive and architectural coatings, cosmetics, plastics, printing inks and more.