Download Our Infographic for Solutions on How to Transform Your Printing to Sustainable Flexible Packaging

Sun Chemical has taken proactive leadership in research and development to bring solutions to the flexible packaging market that achieve both the printing quality and requirements of converters  and the sustainability goals the industry is aspiring to achieve. Some examples include:

and the sustainability goals the industry is aspiring to achieve. Some examples include:

- Efficiency improvements

- Waste reduction

- Safety and integrity of food and beverages

- Extended quality and shelf-life of packaged food products.

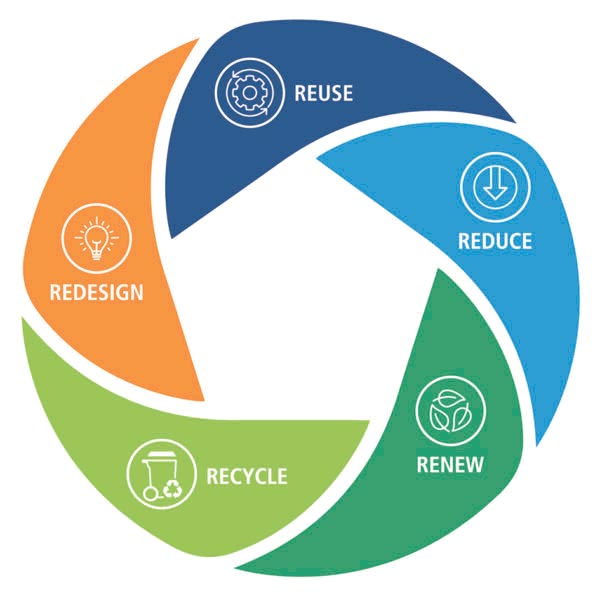

Drawing from our 200+ years of knowledge and experience in the flexible packaging market, our approach to sustainable product development includes risk management and eco-efficiency improvements, as well as a proactive approach in working with suppliers, customers, and industry trade groups to promote best practices. Using our 5Rs framework (Reuse, Reduce, Renew, Recycle and Redesign) as a guide, Sun Chemical invests significantly in R&D to improve the eco-efficiency and sustainability of packaging that utilizes its inks, coatings and adhesives to support a circular economy.

Inks, coatings and lamination adhesives may only be 1-3% of a finished package, but while they may be small in volume and weight, they could make or break the sustainability credentials of flexible packaging. Download our infographic to learn:

-

- what the sustainability landscape looks like in flexible packaging

- what that means for converters and brand owners

- how our solutions can help meet your sustainability goals

By choosing to operate more sustainably, your print operation will not only play a vital role in helping to reduce waste and lower global CO2 emissions, it can also cut costs, boost business growth and significantly enhance public perception. We invite you to download our infographic to learn our solutions for the flexible packaging market can help your business achieve its sustainability goals.

By choosing to operate more sustainably, your print operation will not only play a vital role in helping to reduce waste and lower global CO2 emissions, it can also cut costs, boost business growth and significantly enhance public perception. We invite you to download our infographic to learn our solutions for the flexible packaging market can help your business achieve its sustainability goals.